Italy cheese business DalterFood Group has a business model based on exports and serves 32 countries.

However, with the UK as its most important market the company has been impacted by the recent implementation of post-Brexit rules that include additional checks at the border and increased import tariffs.

General manager Andrea Guidi is a food industry veteran. A former Nutkao and Barilla executive, his career also includes three years as head of balsamic-vinegar supplier Acetum, where he was at the helm when it was sold to Associated British Foods. He spoke to Just Food’s Andy Coyne about post-Brexit woes and other issues.

Andy Coyne (AC): Just to understand your business model, it is very much based around exports. Is that correct?

Andrea Guidi (AG): Yes, as a dairy production group our focus is very much on Parmigiano Reggiano and exporting it. More than 80% of our turnover is generated abroad. Our key export markets are the UK, Germany and France.

AC: How did such a business model evolve?

AG: The company is 45 years old and for historical reasons we became focused on the UK. It has worked well for us. The way we control the supply chain all the way to the shelf allows us to know the names of the cows the milk comes from. That is much appreciated by UK customers, as are our efforts in sustainability.

AC: Tell me about your operation in the UK.

AG: In the UK we have a subsidiary, Dalter UK, that is 100% controlled by us. It is involved in sales, marketing and distribution. The focus in the UK is on Parmigiano Reggiano, which accounts for 60% of our turnover overall.

Access the most comprehensive Company Profiles

on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Company Profile – free

sample

Your download email will arrive shortly

We are confident about the

unique

quality of our Company Profiles. However, we want you to make the most

beneficial

decision for your business, so we offer a free sample that you can download by

submitting the below form

By GlobalData

In the UK, we partner with important retailers such as Sainsbury’s and M&S. We are also in the B2B area. We sell our Parmigiano through food companies to use as an ingredient. These may be manufacturers making ready meals which use our cheese as a hero ingredient. We supply this mainly grated or shaved.

AC: You see your supply chain as a USP?

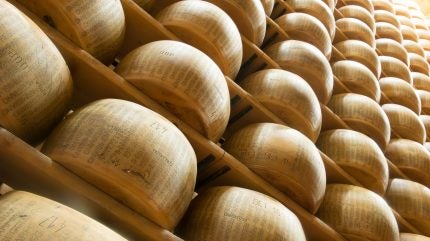

AG: Yes. In Parmigiano Reggiano our supply chain is extremely integrated. It starts from milk collection from 45 farms with which we have exclusivity agreements. We bring the milk to our two cheese facilities in the hills of Reggio Emilia and produce more than 230 wheels of cheese a day.

It is aged on average for two years but some for 18 months or 36 months depending on the product. The wheels are transferred in every way possible from slices and small bags of grated cheese up to big bags of 10k grated. Our two facilities are effectively dedicated to Sainsburys and M&S.

In Germany, we sell mainly other products, not Parmigiano. The market there is much more oriented towards Grana Padano.

AC: Why is the UK such an important market for you?

AG: The UK market will pay a little bit more for quality and that’s not always true in every market. UK retailers are obsessed with quality and control of the supply chain.

AC: And you prefer to sell on a private-label basis rather than having your own brands?

AG: Yes. For historical reasons, we started selling in the UK to big retailers for their own labels. It was the way the company grew up.

AC: All of which must mean that the recently-implemented post-Brexit import controls at the UK border for produce from the EU is burdensome for you?

AG: There are additional costs linked to an increase in import tax as well as additional checks on the border. This increases costs for us and we will be forced to change our prices. It will increase prices for English customers.

AC: Presumably, you have already had to do that because of inflation in your supply chain, logistics operations etc?

AG: In 2022 and 2023 it [inflation] was a very big problem that we tried to tackle in partnership with our customers and suppliers. It was an issue for everyone. We tried hard to work with them to increase the level of efficiency in the supply chain but we were forced to increase prices. We had to do it in order to survive.

AC: What was the response from retailers?

AG: Our way is to have open discussions but customers are never happy with price increases so a certain type of conversation had to be had. But the situation was such that nobody was able to refuse it.

AC: What’s your current turnover?

AG: In 2022, our turnover was €145m ($157.7m). It’s not official yet but in 2023 it is likely to be €160m.

AC: What is you strategy moving forward? Are you targeting any new markets?

AG: Our strategy is to reinforce our presence in markets we are in at the moment and not to focus on new markets. We focus on our commitment to sustainability and creating quality products.

AC: What sustainability efforts have you made?

AG: We have invested in our dairies and want to implement systems across the whole group. We want to produce all our own energy by 2025. We are also working a lot around animal welfare. This is becoming more and more important. There’s a big push on this.

We are also working to make packaging sustainable and recyclable across our products. UK retailers are extremely demanding on us [in this area]. It makes us improve the overall sustainability footprint of our company. In other countries it is not as appreciated as it is in the UK. But we wanted to do it anyway because our shareholders push us to do it.

AC: Parmigiano Reggiano has EU Protected Designation of Origin (PDO) status of course, meaning that only cheese produced in specific regions of Italy can be labelled as what we call parmesan in the UK. Does this protection work in practice?

AG: It’s a very big issue. Our Parmigiano Reggiano suffers from Italian sounding products. We try to put pressure on companies producing fake parmesan cheese but it is a never ending fight. But if we focus on competition from other Parmigiano producers, our control of our supply chain gives us a competitive advantage and helps us to defend our position. It’s not easy for other companies to build such an integrated supply chain.