Concordia College researchers have discovered some way to make use of sound to solidify liquid into plastic, a 3-d-printing way that may be used to build scientific implants immediately within an individual’s frame.

The researchers’ way, known as direct sound printing (DSP), focuses extremely high-frequency sound waves on a place of liquid resin for just a trillionth of a 2d, the researchers stated this week. It is very transient however very robust, inflicting a tiny bubble to shape that has sufficient power to cause a chemical response that solidifies the resin.

3-d printing, whilst no longer as economical as mass production strategies like injection molding for plastic, has been catching on in some spaces. That incorporates making prototypes, growing one-off merchandise like custom designed soccer helmets and development shapes which can be unimaginable with typical strategies.

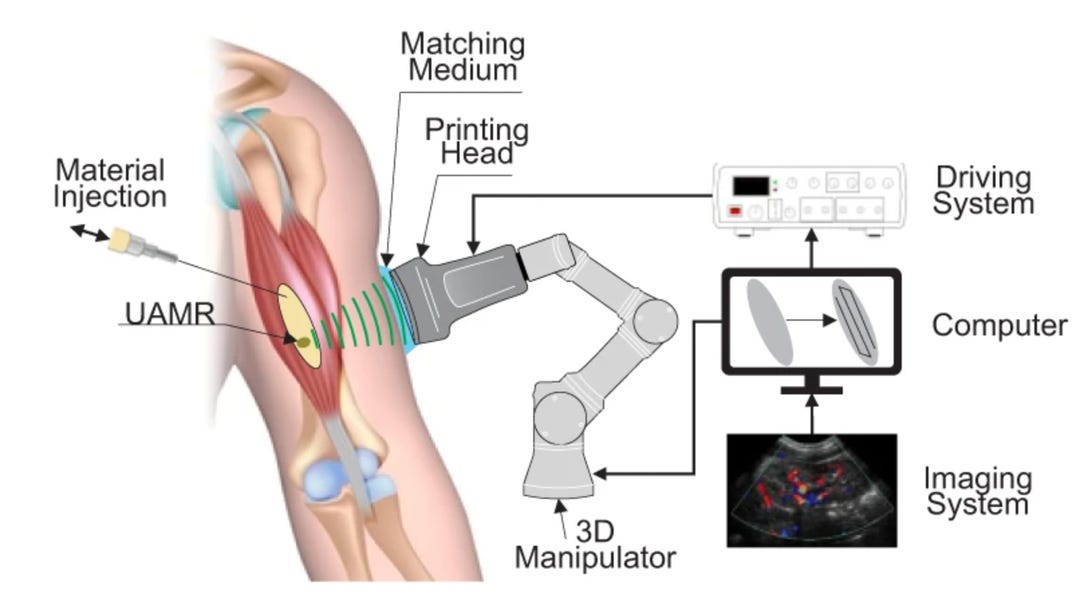

Sound-based 3-d printing may upload a brand new trick to the additive production business. Cast fabrics ceaselessly block warmth and light, however sound can achieve within a frame or instrument. That would result in production an implant throughout the frame as a substitute of surgically including one thing made outdoor. The researchers examined the era running via 1.3 inches of pig pores and skin, muscle and fats tissue.

“DSP introduces the potential of noninvasive deep within frame printing,” Concordia researchers stated in a Nature Communications paper. One of the crucial prototypes the researchers made come with ears and noses, however they did not assemble or implant the rest within sufferers.

Sound waves can penetrate flesh, doubtlessly which means 3-d printing may assemble an implant within a reservoir of subject matter within an individual’s frame.

Concordia College

3-d printing already is used for scientific and dental procedures like substitute bones and enamel straighteners. Some docs even discovered a solution to 3-d-print a substitute ear out of the affected person’s personal cells.

Maximum 3-d printing solidifies fabrics the use of mild or warmth. Sound gives a unique solution to direct power to the appropriate spot, forming a small bubble via a procedure known as cavitation. There, temperatures achieve drive about 1,000 occasions that of air at sea stage and about 27,000 levels Fahrenheit — significantly warmer than the outside of the solar that is close to 10,000 levels.

That is an intense surroundings, however it is very small and really short-lived, so it does not have an effect on the encircling areas.

The sound founded 3-d-printing way additionally may paintings with mechanical maintenance, for instance servicing differently inaccessible elements within airplane, the college stated.

The process works on different fabrics but even so polymer resin, too.

“We proved that we will be able to print more than one fabrics, together with polymers and ceramics,” Concordia researcher Muthukumaran Packirisamy stated in a observation. “We’re going to check out polymer-metal composites subsequent, and in the end we need to get to printing steel the use of this system.”