MARCY, New York — From afar, the brand new Wolfspeed manufacturing facility in upstate New York looks as if some other massive company place of work development, with an unassuming grey external and big glass home windows. However hidden inside of is a high-tech plant that’s virtually completely operated by means of a fleet of robots programmed to construct semiconductors with a excessive stage of precision. The scene is a some distance cry from the guide hard work of the Twentieth-century Ford meeting line, and it simply could be the way forward for American production, no less than in line with the politicians and bosses who celebrated the plant’s grand opening in past due April.

To mark the instance, a couple of hundred folks, together with Wolfspeed staff, traders, and native officers, accumulated in a big tent only a quick stroll clear of the manufacturing facility’s entryway. A chain of audio system, together with Wolfspeed CEO Gregg Lowe, took turns boasting in regards to the plant’s significance — for native jobs, for era, for preventing local weather trade, or even for American prosperity. Additionally in attendance used to be Eric Bach, the executive engineer of Lucid Motors, an electrical automaker that, only a few hours previous, introduced it could get started the usage of Wolfspeed’s chips in its cars. The celebrity of the display: New York Gov. Kathy Hochul, who claimed the brand new facility used to be a part of the “biggest comeback within the historical past of this country” sooner than she took a spin in one of the crucial luxurious Lucid EVs.

“This has to occur. Not can the rustic, the US, be delivered to its knees on account of provide chain problems,” Hochul instructed Recode. “Lead them to right here! Lead them to in New York! We’ll put the cash at the back of it.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426582/GreggHochulFabWindow_a.jpg)

Wolfspeed’s manufacturing facility is opening its doorways after greater than two years of a world semiconductor scarcity that left vehicles with out portions and the well being care machine low on clinical units. To supply extra chips, the Biden management, with the assistance of state governments, now plans to speculate $52 billion within the chip trade to construct extra factories similar to the brand new plant outdoor Utica, New York. The hope is that those crops gained’t simply make extra semiconductors; they’ll spur a tech production renaissance in the similar nation that invented the pc chip and produced Silicon Valley a long time in the past.

This new crop of chip factories, also known as fabs, gained’t be in a position in time to unravel the present chip scarcity. Those amenities will take years to construct, and even if they’re finished, they gained’t produce as many chips as the United States makes use of. Nonetheless, the federal government thinks the fabs may just play a essential function in blunting the affect of a long run disaster, like local weather trade or some other pandemic. In addition they may lend a hand the United States regain management within the trade it created and catch as much as Taiwan, which makes virtually the entire international’s maximum complicated chips as of late.

What’s unclear, on the other hand, is whether or not investment the development of latest fabs will likely be sufficient to make that occur. Development a unmarried fab is a big business mission, so development a number of — briefly — will likely be a colossal endeavor. To an extent, the United States is making an attempt to cultivate era that, for many years, has been produced by means of a world provide chain made up of hundreds of businesses, because of this the good fortune of those new fabs might nonetheless rely on different portions of the arena. Or even because the White Area races to assert a larger proportion of the arena’s general chip production, different nations, together with Taiwan, are looking to do the similar factor, because of this there’s no ensure the United States will finally end up with the higher hand that it needs.

How The united states misplaced its selfmade chips

The USA as soon as ruled chip production. In 1947, scientists at Bell Labs created the arena’s first transistor, a elementary digital transfer, that may flip a sign off and on. This element become the root for the built-in circuit, often referred to as a pc chip, which packed more than one transistors right into a unmarried instrument. Because the era advanced, new corporations started competing now not simplest to design chips with extra transistors, but additionally to provide those chips at scale. Prime-tech production corridors emerged in Texas and what become Silicon Valley, paving the best way for complicated client units and home equipment, regularly constructed with chips made in The united states.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426601/GettyImages_528775306.jpg)

The federal government performed a pivotal function in ensuring the United States led the rate in this era. The Protection Division used to be regularly the primary buyer for early semiconductor startups, and govt officers infrequently required corporations to proportion their designs in order that different corporations may just use them, too. This beef up funded preliminary analysis that those chip corporations another way couldn’t have the funds for and laid the root for the tech trade we now have as of late. The USA used this investment technique — also known as business coverage — once more within the past due Nineteen Eighties when it spent $900 million on a partnership referred to as Sematech, through which American chip corporations attempted to make certain that they wouldn’t be overtaken by means of rising competition in Japan. For a time, the program succeeded.

However in fresh a long time, the United States govt has invested much less and no more in its homegrown chip trade, whilst different governments together with Japan, Taiwan, South Korea, and, extra lately, the Ecu Union and China, have invested extra. Those large subsidies — together with decrease hard work prices — have made it a lot inexpensive for American corporations to fabricate semiconductors out of the country. Some also have taken a “fabless” manner, and centered their complete industry on researching and designing chips reasonably than making them. In consequence, simply 12 p.c of the arena’s chip production takes position in the United States as of late, in comparison to 37 p.c in 1990.

This shift has benefited one corporate particularly: Taiwan Semiconductor Production Corporate, or TSMC, a Taiwanese chipmaker that manufactures chips on behalf of alternative corporations. There’s a race to make smaller transistors — so extra of them can are compatible onto a unmarried chip — and TSMC is recently profitable. On account of all of its production enjoy, Taiwan now makes 92 p.c of chips, together with probably the most complicated semiconductors in the marketplace as of late, that have transistors which are not up to 10 nanometers extensive. None of those complicated chips are recently made in the United States, which makes officers very anxious.

“It’s a extremely concentrated provide chain in positive portions of the arena like Korea and Taiwan, and that has made our economic system actually liable to disruptions as a result of small occasions in nations may end up in massive value will increase for American customers and big shocks to US GDP,” Sameera Fazili, the deputy director of the Biden management’s Nationwide Financial Council, instructed Recode. “They’ve probably the most complicated modern chips, while we eat over 30 p.c of the ones chips.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426636/GettyImages_536193612.jpg)

This worry is founded, partially, on fears that China might invade Taiwan sooner or later and try to take keep watch over of its chip-manufacturing capability. However there are different causes to be anxious in regards to the state of US semiconductors. The USA doesn’t recently make very lots of the most elementary, or legacy, chips, which might be normally produced the place they are able to be made for much less. Those are the chips that become unavailable all over the pandemic, and that made a lot of era laborious to search out and drove up automobile costs. The USA may also wish to manufacture extra chips to handle its grasp at the auto trade, since EVs will most probably want no less than two times as many chips as their gas-powered opposite numbers do.

How one can construct a chip manufacturing facility

To make its chips, Wolfspeed makes use of silicon carbide, a semiconducting subject material that’s particularly helpful for chips that energy motors, like the ones in EVs. This silicon carbide comes within the type of translucent discs referred to as wafers, which might be delivered from some other Wolfspeed plant in North Carolina. That facility has a different furnace that will get part as sizzling as the skin of the solar, which is had to refine the fabric. As soon as those silicon carbide wafers are brought to Wolfspeed’s facility in Marcy, they’re despatched to a producing flooring, the place a small military of robots slowly transforms them into sheets of chips.

Chipmaking is very refined — the tiniest speck of mud or human hair can taint a whole batch — so Wolfspeed refines its wafers in a cleanroom, a extremely monitored production flooring with tough air filtration programs. Inside of this cleanroom, robots commute wafers between production steps whilst technicians track their process from a close-by keep watch over room. This procedure comprises lithography, when tiny patterns are published into the wafer, and one thing referred to as deposition, which comes to including layers of metals onto the silicon carbide. As soon as the ones steps are finished, the wafers are despatched to some other facility the place they’re diced into particular person chips. All the operation is computerized, and at the uncommon instance that employees do wish to input the cleanroom, they have got to put on astronaut-like protecting equipment, together with a complete bodysuit, a face defend, and boots.

Making chips is an intricate procedure, however development a manufacturing facility that may do this kind of production is much more sophisticated. For something, fabs can’t cross simply anyplace. They wish to be just about a competent supply of electrical energy, since they are able to use as a lot power as 50,000 properties in one yr (they liberate a lot of carbon emissions, too). Those factories additionally wish to be close to a big frame of water, which they use to scrub and funky down their apparatus, which, in flip, produces wastewater that must be handled. And it’s higher in the event that they’re now not in particular just about any airports or geological fault strains; seismic process can disrupt the extremely exact equipment they use.

Then there’s the topic of the availability chain. Past the fab, creating a chip can contain 70 other border crossings and greater than 1,000 steps, and a unmarried disruption in a single nation or all over a specific step can throw all of the procedure off direction. That’s as a result of there are typically only a few, if any, different choices for provides when one thing is going unsuitable. For instance, only one corporate within the Netherlands, ASML, makes the specialised, $200 million lithography gear that many complicated chip fabs depend on. And simply two corporations, each founded in Ukraine, provide about part of the specialised neon fuel that fabs during the arena use to keep watch over those lasers. In fact, securing all this apparatus has gotten much more tough all over the pandemic.

“We couldn’t get this. We couldn’t get that,” John Palmour, Wolfspeed’s leader era officer, instructed Recode. “It used to be only a consistent provide chain scramble.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426657/Wafer_a.jpg)

All of this implies the price of development a groovy can vary from $1 billion to $20 billion, relying at the complexity of the chips which are being manufactured. That is the principle explanation why that the new surge in call for for chips — fueled partially by means of the call for for extra laptops and extra vehicles — didn’t straight away lead to extra chip fabs. As a result of those crops take years to greenlight and assemble, chip corporations aren’t desperate to spend billions on development extra factories, since call for may just all the time subside. That is partly why governments regularly intrude and supply incentives to construct extra chip factories.

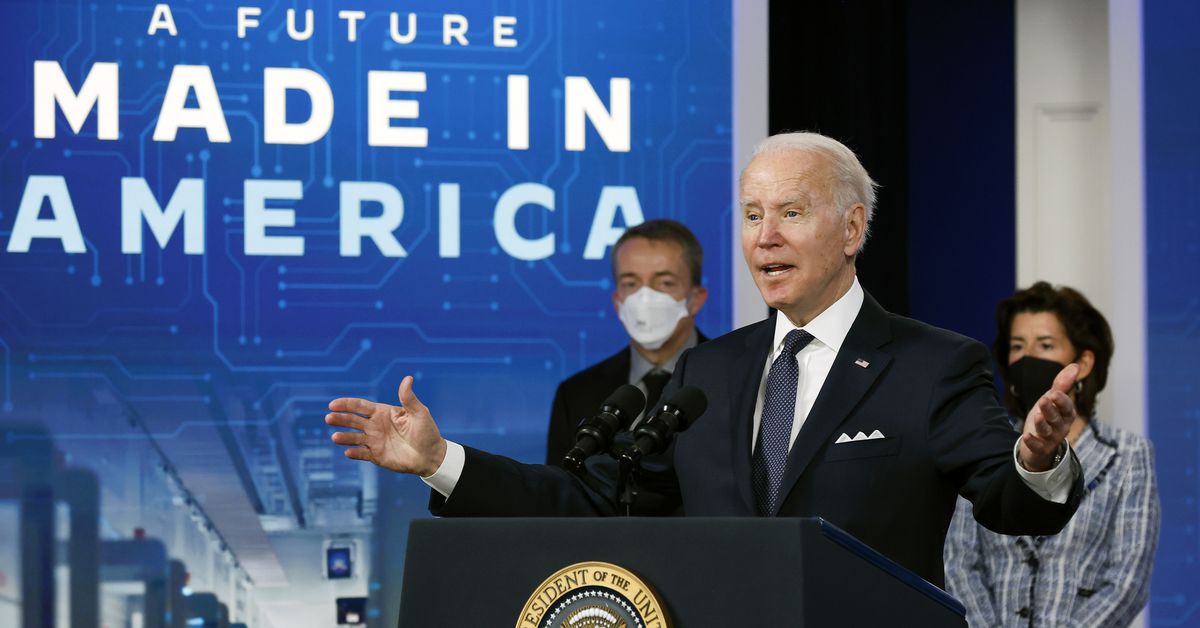

Working example: New York officers spent a long time making an attempt to draw a semiconductor corporate to Marcy, the place New York state has funded a nanocenter related to the SUNY Polytechnic Institute. Wolfspeed simplest agreed to take over the website after some other corporate sponsored out and New York introduced to subsidize the fab with a $500 million grant — about part of its general development prices. Now, much more cash is at the horizon, now not only for some other Wolfspeed manufacturing facility, however for in all probability even larger fabs, together with a new $100 billion megafab in Ohio constructed by means of Intel, which the management is hoping will regain “the forefront” and get started development the similar roughly complicated chips that TSMC makes. President Joe Biden, in his most up-to-date State of the Union cope with, stated that this facility, as soon as it’s constructed, may provide as many as “10,000 new good-paying jobs.”

The massive chip guess

Ahead of any of that may occur, officers say the United States must go a $52 billion package deal referred to as the Chips Act, which might subsidize the development of a number of new fabs. Lately, the invoice is packaged inside of a broader proposal referred to as the US Innovation and Pageant Act, regulation considering competitiveness with China. Whilst the Area and the Senate model of this plan aren’t precisely the similar, the initiative has the beef up of Republicans, Democrats, the White Area, and the most important chip corporations. The beef up from the trade isn’t unexpected; each and every of those corporations may just theoretically obtain as much as $3 billion to construct a brand new manufacturing facility, and some other $2 billion is also earmarked in particular to construct a groovy that will completely focal point on extra elementary chips utilized in vehicles.

Proponents of the large invoice argue that it’s the naked minimal as a result of different nations are nonetheless subsidizing chip production, too. Again in 2014, China introduced a $150 billion effort to spice up its personal semiconductor trade over the following decade, and the rustic has imported fewer and less chips lately. South Korea plans to spend up to $65 billion on its personal nationwide chip initiative. The Ecu Union additionally has its personal $49 billion Chips Act, and its member nations, together with Spain and Germany, will quickly release their very own incentive methods.

“The clock is ticking,” John Neuffer, the CEO of the Semiconductor Trade Affiliation, a industry group that represents American chip corporations, instructed Recode. “Selections are being made as of late as to the place to website the ones fabs.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426699/LucidRibbonCutting_o_a.jpg)

Now not everybody loves this manner; it’s successfully a company subsidy for firms which are already extraordinarily successful. Sen. Bernie Sanders has been extremely essential of the Chips Act, and has stated that chip corporations will have to need to surrender fairness in trade for enormous grants. Others have argued that those corporations would construct new factories in the United States without reference to federal incentives, since in addition they have causes to avoid possible geopolitical battle. And critics indicate that chipmaking isn’t somewhat the jobs-creator that it’s infrequently marketed as, with maximum precise chip production being accomplished by means of automation.

There’s no ensure the investment will paintings. The USA would possibly not have sufficient of the specialised employees that chip production calls for to beef up the choice of fabs that officers need. Will Hunt, an analyst at Georgetown’s Middle for Safety and Rising Generation (CSET), estimates that 8 new fabs might require no less than a couple of thousand overseas employees, since many of those amenities wish to rent folks with earlier enjoy operating in semiconductor production. Every other worry is that the United States’s long regulatory and allowing procedure may just decelerate the development of latest factories, and the United States already builds new fabs at a slower charge than nations in East Asia. Even after those amenities are built, they would possibly not produce the choice of chips or jobs that corporations promise.

A senior financial reputable on the White Area instructed Recode that whilst the $52 billion will spice up American chip production, it gained’t be sufficient to provide the choice of chips the United States consumes. Nonetheless, the federal government thinks that gaining this production experience may well be essential all over a long run emergency. In spite of everything, the pandemic has illustrated time and time once more that after provides are quick, nations will attempt to protected the arena’s maximum sought-after merchandise — whether or not it’s chips, mask, or vaccines — and may also use them so that you could affect world family members. Governments would reasonably different governments be depending on them than the opposite direction round. In different phrases, they would like bargaining chips.

So it’s now not unexpected that semiconductors have change into that leverage. Those tiny little chips are ubiquitous and feature change into a need in the general public’s on a regular basis lives. There’s no indication that’s converting anytime quickly, particularly since extra tough units — which use much more tough semiconductors — are all the time being rolled out. So long as the arena will depend on this era, nations will need as a lot keep watch over over chips as they are able to get. That implies that even with Wolfspeed’s manufacturing facility now open for industry, the United States nonetheless has an extended highway forward.