With innovation at its core, the world of food and beverages is an ever-evolving landscape. In recent years, Forward Osmosis (FO) has emerged as a technology worth attention, revolutionising the way we preserve the delicate taste and smell of our favourite food and drinks.

Understanding Forward Osmosis

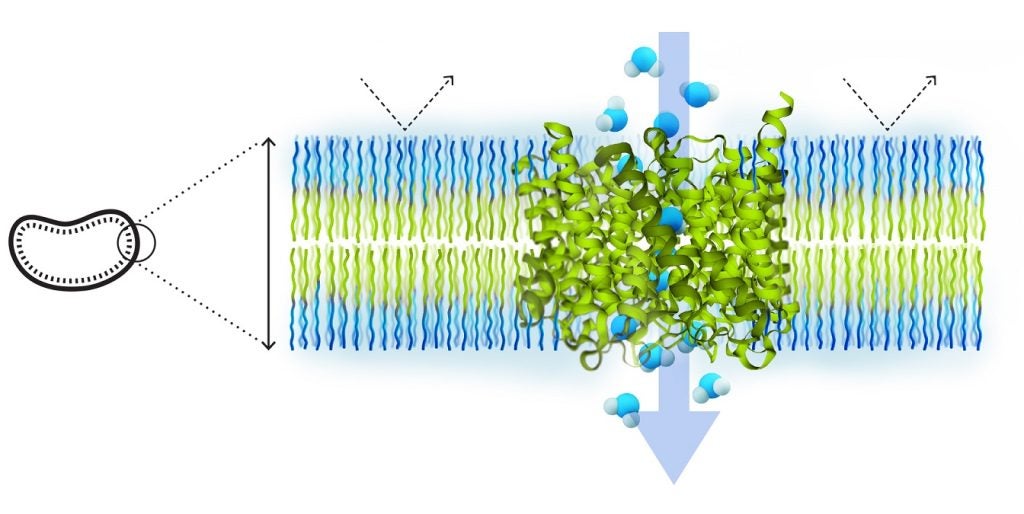

FO involves removing a concentration gradient through the movement of solvent or water through a semi-permeable membrane. Water moves from a solution with lower solute concentration (the feed solution) to one with a higher solute concentration (the draw solution). The water dilutes the draw solution while concentrating the feed solution. This principle forms the foundation for numerous applications in the food and beverage industry.

Why Forward Osmosis stands out

FO really shines when it comes to preserving the flavour of food and beverages. Traditional food concentration methods often involve high temperatures and long exposure times which can lead to flavour degradation. With FO, the gentle concentration process minimises heat exposure, preserving the valuable aroma of the product. It is particularly beneficial for delicate flavours, such as those in cold brew coffee, juice and tea – ensuring that consumers experience the full spectrum of natural flavours.

Second, energy efficiency is a massive advantage of FO. Traditional methods of concentration often require energy inputs for heating and cooling. FO, however, relies on osmotic pressure differences, which significantly reduce the need for energy, making it a sustainable choice for manufacturers. This translates to lower production costs and reduced environmental impact.

Third, nutrient retention. Like flavours, nutrient retention is a top priority in food processing, as consumers increasingly seek healthier options. FO minimises the loss of essential nutrients during the concentration process. As the water moves from the feed solution to the draw solution, the solutes and vitamins remain trapped in the feed solution. The products both taste better and maintain higher nutritional value.

Applications of Forward Osmosis

The benefits of FO in the food and beverage industry are wide-ranging, and this technology finds applications in numerous areas, for example:

Cold Brew Coffee Concentrates: FO is employed in the production of concentrated cold brew coffee where heat through the product is minimised.

Fruit and Vegetable Juice: Juices are susceptible to heat and so FO is used to concentrate fruit and vegetable juices safely, ensuring their natural flavours and nutrients remain intact.

Aqueous (water-based) aroma from Spinning Cone Column (SCC) technology: Flavour producing companies around the world are already benefiting from the unique ability of the SCC to capture aroma compounds from foods and beverages in an aqueous format. Concentrating these fractions further has had its challenges. With FO technology, however, this has been overcome.

Flavourtech has recently partnered with Aquaporin A/S, a Danish company producing FO membranes and systems. Aquaporin’s Inside® FO membranes are key to the further concentration of aqueous aroma solutions post Flavourtech’s SCC. When it comes to the sale of these products, manufacturers must contend with the cost of logistics. Being able to reduce the cost of logistics by reducing the volume of product to be shipped and maintaining product quality is of utmost importance.

Usually, concentration will involve a heating step – such as in an evaporator – where temperature is applied to remove water. FO does not. The FO process separates the water from the aqueous aroma while maintaining the integrity of the product, resulting in a high-quality concentrated aroma/flavour product.

Aquaporin’s FO membranes also have the advantage of being highly selective with higher “rejection rates” of solutes, aroma compounds and nutrients, meaning that these important components stay within the concentrate and are not lost.

Looking to the future

Forward osmosis is a technology that promises to transform the food and beverage industry. Its ability to retain flavour, reduce energy consumption and preserve nutrients, makes it an invaluable tool for manufacturers seeking to create high-quality, sustainable products.

As the demand for healthier, more natural food and beverages grows, Flavourtech’s partnership with Aquaporin, and their innovative approach to concentration, holds the potential to improve the taste experience of myriad food and beverage products for consumers.

Many F&B trailblazers are already adopting FO technology – and, by working with the right partner, you could benefit too. Download the whitepaper on this page to find out more.

Flavourtech is an Australian manufacturer of unique processing equipment for aroma recovery, dealcoholisation, extraction and evaporation that help food, beverage and pharmaceutical companies differentiate their products. Download the whitepaper on this page to find out how to contact Flavourtech, or contact flavourtech.com to find out more.