Inside a nondescript building on Samsung’s campus in Suwon, South Korea, workers sit in cubicles typing away at their desks. Leaf-shaped awnings hang overhead to provide some shade from the bright office lights. But once you leave the main office area and turn a corner, the workplace starts to look a lot different.

Tucked away in hallways throughout the floor are Samsung’s reliability testing labs. It’s where Samsung tortures its phones before shipping them out to the millions of people buying them around the world. Robots drop phones on metal surfaces, water jets pummel mobile devices from all directions, and chambers immerse gadgets in extreme temperatures.

It’s all part of Samsung’s process to ensure its phones can withstand drops, dunks, extreme climates and other hardships. This type of testing is critical because phones are expensive and essential to daily life, so they must be built to last.

Samsung is no stranger to reliability issues. It infamously recalled the Galaxy Note 7 in 2016 because of overheating issues and delayed its first foldable phone launch in 2019 after some reviewers experienced broken screens. Last year, reports of batteries swelling inside Samsung phones surfaced on YouTube.

CNET and other journalists got a rare glimpse inside Samsung’s lab to see how it stress tests devices. The tour provided a sense of how Samsung thinks about durability when it comes to phones — not just the tests themselves but also the types of scenarios Samsung accounts for. That’s important because Samsung ships more smartphones than any other company worldwide, according to the latest figures from market research firm International Data Corporation.

Samsung’s foldable phones go through several drop tests and other types of durability assessments.

When thinking about whether your phone is durable, the first thought that likely comes to mind is whether it can survive drops. According to a 2020 study from AllState Protection Plans, 140 million Americans have damaged their phones at some point in their lives.

And Samsung’s facility has plenty of machines at work to account for all the different ways you might throw, crack or shatter your phone. It’s not as simple as just dropping the device over and over again. The tests in Samsung’s lab are designed to evaluate how phones react when falling at different angles and heights, while also zeroing in on specific parts of the phone, like the screen and cover glass.

One such assessment known as the tumble test involves putting devices in a giant rotating rectangular chamber, where they’re tossed around over and over again. This test is meant to examine how phones hold up after being hit from different angles.

Samsung’s phones go through a tumble test to assess their durability from multiple angles.

In another corner of Samsung’s facilities, I almost cringed as a steel ball dropped directly onto the screen of a Galaxy Z Fold. For this test, Samsung is measuring how durable the display, back glass and internal parts of a device are after enduring impact.

One of Samsung’s phones undergoes a durability test to see how it holds up after a metal ball is dropped onto the device.

For less dramatic tumbles, Samsung has a low drop test. A machine suctions up a device and drops it from a lower height, which is meant to simulate what the cumulative effects of flicking your phone across the table could be. Although this test doesn’t look as brutal as the others, it shows that Samsung is thinking about how minor slip-ups could impact a phone’s condition over the long term.

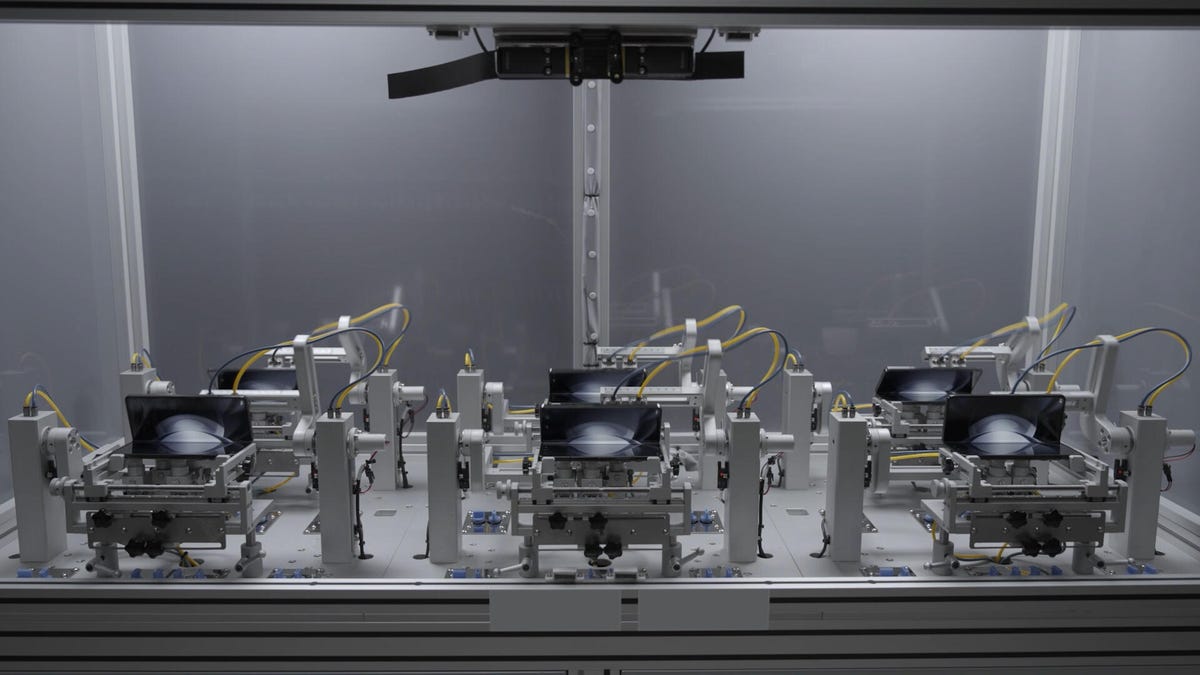

Foldable phones require their own special testing. I watched as robotic arms opened and closed Galaxy Z Flips and Folds over and over again almost in rhythm. When asked how many open-and-close cycles these devices must go through to pass the test, the member of Samsung’s reliability team giving the tour simply said “a lot of times.”

The goal is to understand how many times the average person would fold and unfold their device in a given period during regular use, the Samsung employee said through a translator. Such durability tests are particularly important for foldable phones. A quick Google search turns up dozens of stories of broken screens on the Z Flip across Reddit, YouTube and Samsung’s community forums. Samsung says the Galaxy Z Fold and Z Flip are tested to outlast 200,000 folds, or roughly five years of use if unfolded 100 times per day.

Samsung’s foldables undergo a test in which they are opened and closed over and over again.

After a decade of reviewing tech products, I’ve become accustomed to deciphering ingress protection ratings, or the scores that tell you whether your phone is water or dust resistant. What I haven’t seen, however, is exactly what the testing behind those ratings looks like in real life.

Samsung’s reliability lab has various machines to test for different levels of water resistance. I watched as water jets soaked a Samsung phone as part of the company’s testing for the IPX4 rating, which ensures that phones can endure being sprayed with water. In the same room, a phone sat at the bottom of a towering water tank to test for more demanding ratings like IPX8.

Samsung’s foldable phones are sprayed from all angles to test their water resistance rating.

Resistance to drops and dips in the pool may be the first scenarios that come to mind when you consider whether a smartphone is durable. But Samsung has dozens of other tests meant to assess more granular aspects of your device as well. Robots plug in chargers and press the side key continuously to test a phone’s USB port and buttons. Machines drag the S Pen across the Z Fold’s display over and over again to make sure pressure from the stylus doesn’t impact durability.

But Samsung’s testing lab isn’t just an automated torture chamber for phones. The company also has dedicated spaces for testing how phones hold up in real-world scenarios. One such area, for example, is meant to mimic cafes, park benches and restaurants to see how a device’s cameras perform in those environments.

What stood out to me the most is the way Samsung tests whether devices can withstand extreme temperatures. The company has dedicated chambers for immersing devices in extreme cold and highly humid conditions to ensure phones will function properly in climates around the world. The environmental test chamber looks unassuming metal and glass box from the outside, but the stark temperature shift is immediately jarring once you reach inside. One chamber I observed was set to minus 20 degrees Celsius (minus 4 degrees Fahrenheit), although Samsung conducts tests at other lower temperatures too.

Samsung tests whether its devices can withstand extreme temperatures.

Touring Samsung’s reliability lab provides a glimpse into the company’s development process and sheds some light on why new concepts may take so long to graduate to real products. Every time Samsung adds a new component or feature — like folding screens, rounded displays or new S Pen slots — the company likely has to test how those new parts hold up under dire circumstances. Perhaps eventually the wilder concepts Samsung has shown off at CES like flexible sliding displays will make their way to these labs too.