Starting a food manufacturing business covers a wide range of topics and sectors including dairy products, ready-to-eat meals, frozen meals, and so forth. Market Research, the well-known industry research database expects that the global food service market will be growing until a market value of $2,646.99 billion by the end of 2023 and then $5,423.59 billion until 2030 with a CAGR of 10.97% during these 7 years.

Launching your career of entrepreneur into the food industry seems to be lucrative now that you can either service big brands of groceries as well as local consumers around your regional or even at international level, however, you will still need some tips for a successful business project to make sure your food manufacturing business can grow steadily in the future.

TIP 1: Study Through the Applicable Regulations

Depending on your region and country as well as the specific food sector you will be dedicating to, we suggest that you should study into all those applicable regulations to either ensure your compliance and for the purpose to avoid legal issues in the future.

Food Manufacturing has listed several top legal and regulatory issues with food manufacturing and service business back in 2022 some of which are primarily as follows:

1) FDA Updates

FDA stands for the Food and Drug Administration, an agency of the United States Department of Health and Human Services – an official organization that is responsible for protecting and promoting public health by regulating the safety and effectiveness of food, drugs, medical devices, vaccines, cosmetics, and other products.

FDA would update their regulations and definitions around multiple definitions of their terms and conditions which would later lead to issues including changes or updates to labeling regulations, food safety requirements, ingredient restrictions, new regulations for dietary supplements, and other relevant concerns. Especially if you are a food service company located outside of the United States but has international business towards the country.

2) Good Manufacturing Practices (GPMs)

Good Manufacturing Practices (GMP) are a set of guidelines and standards that outline best practices for ensuring the safety and quality of food during its production, processing, packaging, and handling.

GMP provides a framework for preventing foodborne illnesses and ensuring the safety of food products. A wide range of guidelines are suggested for maintenance, cleanliness and sanitation, proper handling of raw materials, prevention of cross-contamination, hygienic storage and transportation practices, training of personnel, and record-keeping. Following GMP guidelines helps minimize the risk of microbiological, chemical, or physical contamination that can pose health hazards to consumers.

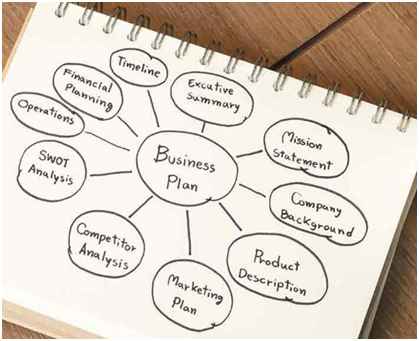

TIP 2: Elaborate a Primary Business Plan

Business plan paves your way towards a successful business model. Just like all kinds of businesses out there, starting a food manufacturing and service business should be based on a written and formal document that serves as a roadmap for the development and operation of the business, as well as to outline the goals, strategies and financial projections which are essential for the decision-making and attracting investment in the future.

For a food manufacturing business, your business plan must include the following concepts:

Market Analysis: Define your target markets like supplying local groceries and supermarkets, or direct to consumers. Then the research and analysis of the target market, including demographics, competition, and trends.

Products and Services: Food manufacturing covers a wide range of categories like ready meals, dairy products, beverages, etc. You should confirm the details the offerings, highlighting their unique selling points and competitive advantages such as delivery services of ready meals, weekly and personalized menus, and so forth.

Marketing and Sales Strategies: How would like to promote your brand and products? How about your strategies for marketing either Online or Off-line?

Funding Request and Exit Strategy: If seeking funding, this section outlines the amount and purpose of funds needed, as well as potential exit strategies for investors.

Operations and Management Plan: Describes how the food manufacturing business will be run on a day-to-day basis, including staffing, processes, food raw materials and resources required.

TIP 3: Looking for Automation Solutions for Mass Production

None of the food manufacturing and processing businesses in the world would count only on manual works for their production considering the large volume of demands from the consumer markets.That is to say, you will inevitably need to implement automated systems and equipment for processing, production and packaging.

A complete line of food processing and production involves a whole range of procedures from the forming of containers to the filing, sealing and then packaging including primary, secondary and tertiary packaging, while for each of the mentioned processes here you will need to find out the corresponding equipment for their automation.

Searching for an adequate packaging equipment is not an easy job. For example, when selecting packaging machine for the primary packaging of food products there are bunches of factors to be considered and assessed including:

Food Safety and Hygiene: Ensure that the machine is designed and constructed to meet food safety standards and regulations. It should be made of food-grade materials that are easy to clean and sanitize to prevent contamination.

Packaging Material: Assess the types of packaging materials the machine can handle, such as pouches, bags, trays, or containers. Ensure that the machine can work effectively with the specific packaging materials you plan to use for your products.

Production Capacity: Determine the desired production output you need from the machine in terms of units per hour or day. Choose a machine that can handle the required production capacity to meet demand without causing bottlenecks or delays.

Flexibility and Adaptability: Consider whether the machine can handle multiple packaging formats or if it is limited to a specific type. Opting for a machine that offers flexibility to adapt to future changes in packaging requirements or product variations.

Alternatively, you can also trust packaging machines made by www.eliter-packaging.com which is a professional manufacturer of secondary packaging machines located in China.

TIP 4: Implement Effective Production Management for your Facility

Keeping a control over your production in a reasonable and scientific manner is a key and critical factor for your productivity.

The modern production management theories can improve safety with your operators, boost your productivity with better ROI, and make full use of your potential manpower and thus to achieve better KPI.

Depending on your management methods adopted like data-based management or with industry 4.0 approach, there are various advantages as follows:

- Improved Traceability and Recall Management: An effective production management system enables proper tracking and documentation of ingredients, batches, and production data. This aids in traceability, recall management, and addressing any safety concerns promptly and efficiently, minimizing potential risks or reputational damage.

- Enhanced Communication and Collaboration: Effective production management promotes better communication and collaboration among different departments involved in the production process, such as purchasing, production, quality control, and logistics. This helps align goals, resolve issues, and drive continuous improvement.

- Enhanced Operational Flexibility: By having a well-defined production plan and optimized processes, a food manufacturing facility can quickly adapt to changing market demands or product variations. This flexibility allows the facility to meet customer needs efficiently while minimizing disruptions or delays.

- Streamlined Inventory Management: Efficient production management helps maintain optimal inventory levels. By closely monitoring demand, production output, and supplier lead times, you can minimize stockouts, reduce inventory carrying costs, and prevent excess or obsolete inventory.

Key Takeaways

Starting a food manufacturing business requires careful planning, attention to quality, and compliance with regulations. Seek advice from industry experts, consult with professionals, and network with peers to gain insights and make informed decisions. Think thoroughly and carefully with all details and factors taken into consideration before taking actions!