The demand for natural flavours continues to grow in the F&B industry. Ultimately, consumers are the winners when they get better quality, natural flavours, true to the raw material they come from. Fruit flavours, such as strawberry and mango, or flavours from botanicals, such as herbs, spices and hop, are now highly desirable.

What Are Natural Flavours?

The term “natural flavours” is subject to robust regulation in both the US and EU. The use of the word ‘natural’ also extends to the labelling of food and beverage products, with the European Union (EU) recently narrowing the use of the wording “natural organic”. From January 2022, new EU regulations mean these terms are treated more seriously across Europe. EU 2018/848 delves into food and beverages labelling and, if the word ‘organic’ is used, the flavour additives contained in the product must have a minimum content of 95% w/w (weight per weight) and be from certified organic material from the named ingredient. So, for example, natural strawberry flavours must contain a minimum of 95% w/w from real organic strawberries and the flavour must be recognised with ease.

Legal distinctions between the term “natural flavours”

United States: essential oil, oleoresin, essence or extractive, protein hydrolysate, distillate, or any product of roasting, heating or enzymolysis, which contains the flavouring constituents derived from a spice, fruit or fruit juice, vegetable or vegetable juice, edible yeast, herb, bark, bud, root, leaf or similar plant material, meat, seafood, poultry, eggs, dairy products, or fermentation products thereof, whose significant function in food is flavouring rather than nutritional.1

Europe: a flavouring substance obtained by appropriate physical, enzymatic or microbiological processes from material of vegetable, animal or microbiological origin either in the raw state or after processing for human consumption by one or more of the traditional food preparation processes (which includes chopping, cutting, distillation and others from a lengthy list).2

Such regulations have been put in place to reduce confusion for manufacturers and provide clarity for the general public on just what they are purchasing and consuming. It must be natural and clean; synthetic or compounded flavours are not ‘in flavour’ anymore. Take, for example, natural flavours extracted from lemon, cherry, strawberry, lychee or passionfruit; these are now termed ‘From The Named Fruit’ or ‘FTNF’ for short.

Extraction of Natural Flavours

There are many ways to capture natural flavours, such as those from fruit, mint, tea, hop and other botanicals. Steam stripping is one such way. Here steam is used to “strip” out volatile aroma compounds, which can then be condensed and captured. However, this technique is fraught with danger; high temperatures and long residence times (time within the stripping system) are often involved, meaning fragile flavour compounds are either damaged or lost during the process.

The Spinning Cone Column

By combining a reduction in temperature with shorter residence times, there is one technology that allows fragile flavour compounds to remain intact and, ultimately, reach the end consumer. The Spinning Cone Column (SCC), manufactured in Australia by Flavourtech Pty Ltd, has been helping companies capture natural flavours for over 30 years.

How Does It Work?

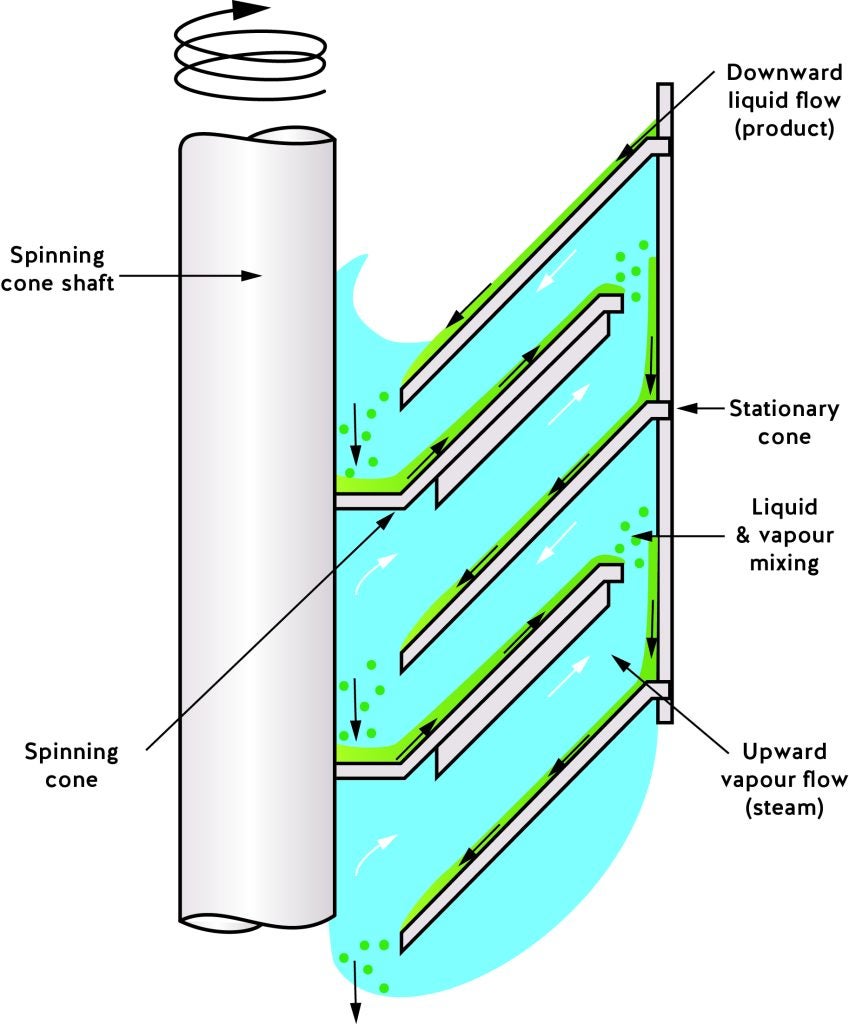

The SCC extracts flavours and aromas via distillation, using steam to separate volatile compounds from liquids, purees and slurries under vacuum pressure. It is a vertical stainless-steel vessel containing a rotating shaft and a series of rotating and stationary cones.

Feed material is introduced at the top of the vessel, flowing down onto the upper surface of the first stationary cone as a thin film (approximately 1mm in thickness) before flowing down onto the first rotating cone. The liquid continues moving down in this manner, cone by cone, before being pumped out at the bottom of the vessel.

Meanwhile, stripping steam is introduced at the base of the vessel and flows upwards taking volatile compounds from the raw material with it. The stripped volatiles are condensed into a concentrated aqueous liquid, resulting in high-quality flavour that is true to the natural characteristics of the raw material. The temperature and flow rate of the steam can be controlled to capture different aroma profiles that may then be used in different product ranges or markets depending on consumer preferences.

Application 1: Natural Fruit Flavours

The SCC is used by Flavour Houses and Food & Beverage companies around the world to extract natural flavours from many different raw materials. One of the most common is fruit. Fruit flavours, such as those from strawberries, raspberries, bananas, mangoes, pineapple and kiwi fruit are particularly heat sensitive and difficult to replicate synthetically. The SCC, however, can readily process fruit mash and puree, enabling it to recover delicate front-end volatiles while avoiding damage to heat-sensitive components. Unlike traditional distillation columns, the technology is not limited to processing clear liquids and juice – which often miss vital top notes or contain heat-derived flavours.

Aqueous fruit essences and essential oils recovered by the SCC can be sold as natural flavourings or used to create premium product lines, adding value to a business’s existing offering. Manufacturers implementing this unique technology are both capturing more market share and securing premium prices due to the superior taste and health qualities of their final product.

Application 2: Natural Hop Flavour

The hop plant (Humulus lupulus) is well known for providing the bitterness in beer as well as the fruity or floral notes prevalent in many craft brews. These notes are typically generated from a process called “dry-hopping” where hop pellets are placed into large bags and then infused in cooled beer. But the dry-hopping process requires lengthy sample handling times and product losses during the filtration step. Many manufacturers are now looking for alternative methods.

A simpler, cleaner process is to employ aqueous hop flavour addition, thus avoiding costs and time losses from dry-hopping and other traditional techniques (like solvent or CO2 extraction). The SCC is proving be the perfect tool for capturing volatile hop flavours. Its unique ability to process slurries of suspended solids – in this case milled hop cones or pellets – allows flavour capture directly from the raw material, rather than from a heat-generated extract.

In addition, the low temperature steam used by the SCC (generally between 45°C to 65°C when processing hop solids) means flavour compounds are recovered without any damage. Residence times within the column are less than 30 seconds. This too avoids damaging natural flavour compounds or forming new heat-derived compounds.

The hop essence collected by the SCC is “true-to-type”, aqueous, non-viscous and clear in colour – making it easy to incorporate into the cold brewing process without organic solvents or carriers. It is easily combined with beer or even water for the production of sparkling hop water products and seltzers. The resulting beverages enjoy significantly enhanced hop flavour and aroma. They are usually preferred by today’s discerning consumer; brewers can’t afford to miss out.

If you would like more information about using the SCC for natural flavour extraction from fruit, hop or any other botanical, please contact Flavourtech or visit flavourtech.com

(1) https://www.ecfr.gov/current/title-21/chapter-I/subchapter-B/part-101 (2) https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02008R1334-20230321