Mass spectrometry is a powerful analytical tool used to determine the composition of gases and vapours in a closed environment through highly sensitive measurements of their molecular mass. When freeze drying sterile pharmaceuticals, mass spectrometry helps manufacturers protect valuable batches from silicone oil contamination – a possible risk of the lyophilisation process.

Preventing silicone oil contamination

Silicone oil is a common component of lyophilisation systems. As a heat transfer fluid, it is circulated through the metal bellows connected to the drying shelves, regulating the temperature during the drying process. Over time, wide fluctuations in temperature and pressure, plus mechanical stress from the automatic up and down motion of the shelves during stopper insertion, has the potential for tiny holes or cracks to form in the bellows. Through these leaks, silicone oil may start to escape.

According to Daniel Kuchenbecker, Market Manager, Medical & Pharma, Pfeiffer Vacuum, a silicone oil leak can be critical for pharma companies. “On the one hand, of course you don’t want to have silicone oil itself inside pharmaceuticals. In addition, the silicone oil circuit is not aseptic like the rest of the sterilised drying chamber. A leak in the circuit could ruin batches of pharmaceuticals, which can have a very high value.”

The EU GMP Annex 1, which provides guidance on the manufacture of sterile medicinal products, was revised and expanded in August 2022. A key focus of the update was the implementation of a robust contamination control strategy throughout manufacturing. The regulation regards lyophilisation as an extension of aseptic processing, thus the importance of checking heating circuits for leaks is now emphasised.

Due to this change in the regulation, more and more companies are showing interest in the opportunity to implement mass spectrometry technology within their freeze drying systems. While other methods of silicone oil leak detection are possible, the ability to perform continuous monitoring and take preventative action with mass spectrometry gives it the upper hand.

“Mass spectrometry is until now the only solution to have in-process monitoring of silicone oil,” explains Kuchenbecker. “Other techniques take place after the batch has been dried, for example through visual inspection of the system. This makes it very tricky to know exactly when that leak occurred and how many batches may be suspicious.”

Mass spectrometry is a fast, reliable, and highly sensitive method of silicone oil detection. The PrismaPro system from Pfeiffer Vacuum detects leaks within seconds. When integrated with a secondary electron multiplier (SEM), detection limits are in the parts per million (ppm) range, enabling manufacturers to rescue batches from a potential source of contamination. Depending on the value of products being dried, a return on investment can be made after just one leakage discovery.

Optimised process monitoring

Silicone oil leak detection is not the only opportunity to leverage mass spectrometry within lyophilisation. “Mass spectrometry is a very versatile technology,” says Kuchenbecker. “You can monitor a broad range of atomic mass units (amu) which can be traced back to certain gases or vapours, and this gives you very valuable information on the progress of the drying cycle.”

For example, by using a mass spectrometer to monitor water vapour content, an operator can precisely determine the ideal time to end the primary and secondary drying stages. Alternative methods such as comparative pressure measurement can be used to this end, but the high sensitivity of mass spectrometry improves accuracy. Meanwhile, by simultaneously tracking nitrogen and/or oxygen levels, external air leaks can be identified, providing an additional layer of security in an aseptic process.

Pfeiffer Vacuum is an industry-leading provider of mass spectrometry equipment, with proven solutions for quality assurance and process analysis in pharmaceutical freeze drying. The PrismaPro quadrupole mass spectrometer is the heart of the setup. Since it needs to work under high vacuum conditions, an appropriate gas inlet system and a high performance turbopump station are integral components as well.

Mobile units can be used for occasional checks for contamination at multiple freeze drying systems. On the other hand, Pfeiffer Vacuum also offers fully integrated mass spectrometer systems which continuously monitor a single freeze dryer and communicate to its programmable logic controller (PLC).

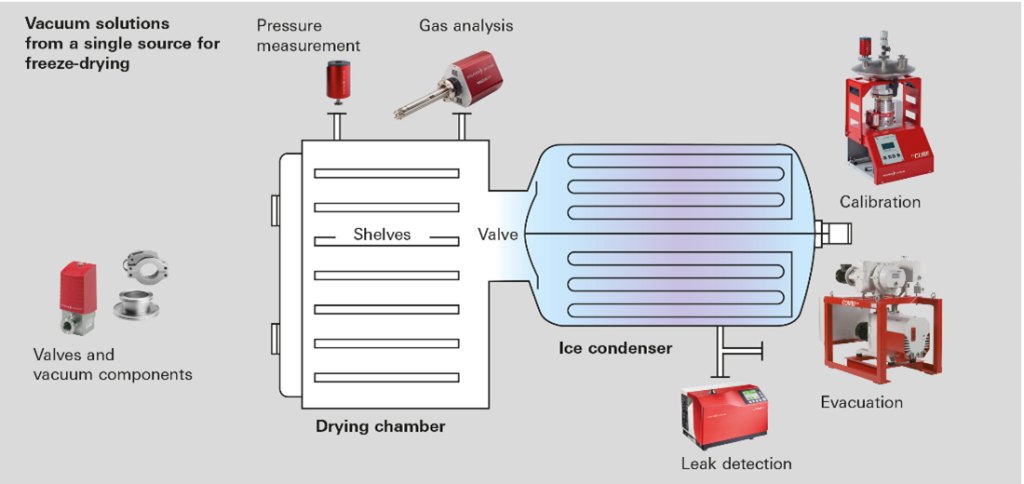

Pfeiffer Vacuum offers a comprehensive portfolio of vacuum products and monitoring solutions for use in lyophilisation processes. To learn more, please watch the webinar below.