We are bombarded with the words ‘Natural’ and ‘Organic’ on a regular basis. Turn on the TV, the radio, or the internet and there will be references to these words associated with food, beverage, or some nutraceutical product. The overuse of any word or phrase inevitably diminishes its meaning or relevance, and there are plenty of examples.

Aquaporin Inside, Natural concentration

The whitepaper explores Aquaporin Inside, a natural concentration technology and outlines how it can mitigate the loss of essential aromas and flavours of food and beverage products.

The technology can be used to retain and enhance the quality of a wide range of products, from coffee and tea extracts to natural food flavoured and alcoholic drinks.

Thank you.Please check your email to download the Brochure.

The demand for better, natural flavours in food and beverages has grown as consumers gravitate towards healthier options and living. Manufacturers have had to adjust accordingly to meet this increased demand, plus contend with new legislations set by governments of countries or regions to meet higher quality standards, natural sourcing, and labelling requirements.

Consider Europe, where from January 2022, new regulations have come into play demonstrating a more serious approach from the EU. The EU 2018/848 delves into the labelling of foods and beverages and if the word Organic is used then the flavours contained in the product must be Natural with a minimum of 95% from the named ingredient. So, natural strawberry flavours must contain a minimum of 95% strawberries itself and the flavour recognised with ease.

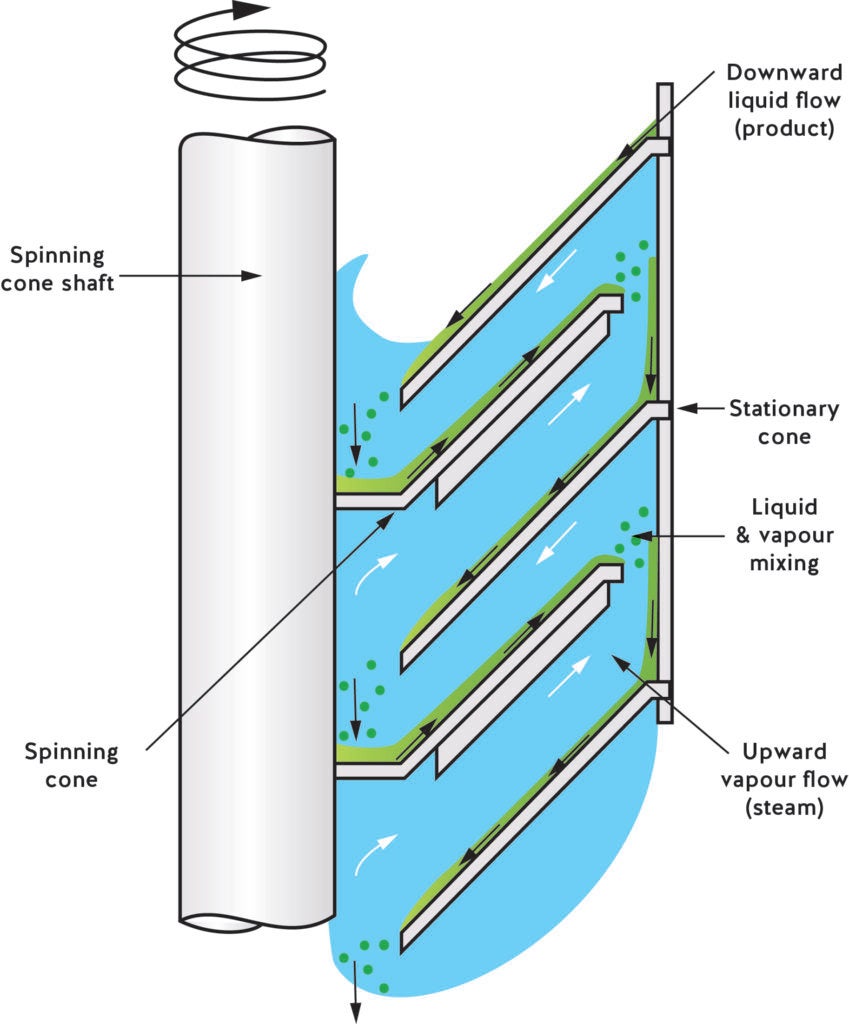

An Australian technology manufacturer, Flavourtech, has been producing systems to enable manufacturers to capture the natural flavours from the named source. Their core and unique technology utilise a spinning cone column (SCC) to ensure the quality of the flavours is of the highest, due to the low residence times and low operating temperatures. So, how does it work?

In order to produce natural flavours and aromas, the SCC employs low-temperature steam to strip or distil the light volatile components that comprise the aroma. We all know steam and how hot it can be; however, the SCC allows the user to control the temperature of steam by controlling the vacuum pressure around it – increasing the vacuum decreases the steam temperature.

So, in this case, low-temperature steam is used to extract the natural fruit flavours which means the flavours are safe and intact. The whole process takes less than 30 seconds! These extracted fruit flavours are concentrated, in water and are fully natural so can easily be combined in beverages and food products.

Fruits such as strawberry, banana, mango, grape, kiwi, apple, orange, pineapple and many more, have had their flavours extracted and are currently available on the market. The extracted aroma is a powerful version of the real fruit flavour.

Flavour houses are already benefiting from the SCC – the flavours are being added to beverages and foods to provide the Natural that consumers are looking for.

Flavourtech has recently partnered with Aquaporin, a Danish company producing Forward Osmosis (FO) systems, to further help in this space. FO is a membrane technique relying on the osmotic pressure difference between two solutions on opposite sides of a membrane.

In other words, water travelling from one side of the membrane with low solids to high, subsequently concentrating the former solution, due to concentration gradients, mimicking cell membranes in the human body. The benefits of this process are low hydraulic pressure, low operating temperature, low fouling of membranes, and the ability to process to higher concentrations.

Aquaporin’s Inside® FO membranes are key to the further concentration of aqueous aroma solutions post-Flavourtech’s SCC. When it comes to the sale of these products, manufacturers must contend with the cost of logistics. Being able to reduce the cost of logistics while maintaining the quality is of utmost importance.

Normally concentration will involve a heating step (such as in an evaporator), where temperature is applied to remove water. FO does not. The FO process separates the water from the aqueous aroma while maintaining the integrity of the product, a concentrate of the aroma is produced.

Start with the Spinning Cone Column to capture the natural flavours from the named source and then concentrate this aqueous phase through the FO technologies. Complex natural flavours from coffee, tea, fruits, vegetables, spices and herbs are captured and concentrated.

Flavour houses as well as food and beverage manufacturers see the benefits of the combination of natural flavour capture and concentration technologies. They provide higher quality products, so the consumers benefit from more health and with better natural flavours. If you would like to be one of the leaders in this field, then please contact Flavourtech.

For further details, please visit Flavourtech.com

Aquaporin Inside, Natural concentration

The whitepaper explores Aquaporin Inside, a natural concentration technology and outlines how it can mitigate the loss of essential aromas and flavours of food and beverage products.

The technology can be used to retain and enhance the quality of a wide range of products, from coffee and tea extracts to natural food flavoured and alcoholic drinks.

Thank you.Please check your email to download the Brochure.