Ahead of a meals merchandise even reaches retailer cabinets, it should go through numerous screening and inspection to be sure that patrons handiest get top quality and protected meals merchandise. That is in particular necessary on account of the danger of infections, diseases, and hypersensitive reactions shrunk from infected meals.

In the US on my own, more or less one in six American citizens get in poor health every yr on account of foodborne diseases led to through pathogens and different ingredients. The most typical pathogen that might get into meals all over production and distribution is Salmonella. Even supposing Salmonella an infection can also be handled, its signs may end up in serious dehydration and demise, particularly for a specific pressure present in floor turkey in 2011 that has change into antibiotic-resistant and inflamed other people in 34 states in the USA.

Salmonella is a kind of micro organism that may reason abdomen ache, fever, and diarrhea. It’s most often present in uncooked and undercooked eggs and meat, unpasteurized milk and dairy merchandise, uncooked vegetables and fruit, and processed meals like peanut butter and packaged meat.

Along with pathogens, different ingredients can touch meals all over manufacturing, equivalent to steel, stones, glass, and plastic. Those international debris would possibly reason lacerations within the inner organs and bowel obstruction when ingested. As a result of those meals contamination problems, a number of meals production firms and fast-food chains have filed for chapter and closed down.

When you’re a meals entrepreneur, you must moderately make a selection and put into effect an inspection device that can assist you ensure that the supply of protected and top quality meals merchandise in your shoppers. You must additionally imagine running with respected execs equivalent to TDI Packsys inspection techniques who can information you all over the method. To get you began, right here’s a information that will help you make a selection the most productive meals inspection device to your meals industry:

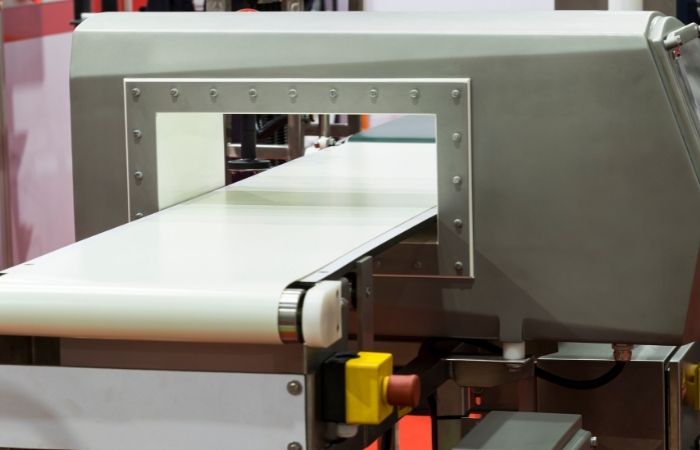

One can by no means inform what twist of fate can occur onsite all over manufacturing. Even a tiny blameless motion may end up in a mishap, say a light-weight staple cord flying its manner against a dough getting blended. You’ll be able to steer clear of incidents like this and the distraught explaining how this would occur when you’ve got dependable apparatus like a meals steel detector for your manufacturing line.

This apparatus can locate ferrous and non-ferrous metals on bakery pieces, meat merchandise, spices, or even sugar. The apparatus works through inspecting the magnetic box within the inspection zone, making sure no steel will probably be provide within the merchandise that you simply’ll distribute in your marketplace.

Imaginative and prescient Programs

Meals presentation and aesthetics also are necessary parts within the meals industry. With the proliferation of social media comes selfies and product pictures uploaded each 2d of each day. Remember that a botched look of a meals product displayed on social media feeds would possibly flip off many attainable shoppers.

Imaginative and prescient techniques supply an answer through scanning packaging for defects and irregularities, making sure that labels and stickers are aligned and fill traces are as much as par. It additionally tests if barcodes are correct and labels are published legibly.

X-ray Inspection Programs

Except steel contaminants, an x-ray inspection device too can locate non-metals like sticks, plastic, bone, and glass. It will possibly additionally locate defects in packaging like breakage, cracks, and displacement. Displaced and improperly screwed bottle caps are extremely prone to getting infected and will reason foodborne diseases. Therefore, having a work of extremely loyal apparatus like an x-ray inspection device can accelerate the manufacturing line with out sacrificing high quality.

Checkweighers

Compliance with weight accuracy is very important within the meals industry. It gained’t simply be sure that your shoppers are happy with the product they’re paying for however may also ensure your profitability ultimately.

Checkweighers reject any underweight or obese merchandise within the manufacturing line immediate and successfully. This may occasionally be sure that your corporation adheres to rules and your shoppers gained’t really feel shortchanged.

Colour Sorters

You could be questioning how all raisins in a package deal glance nearly precisely alike, and no piece with a unique color will get jumbled in. Or a manufacturing unit that manufactures each black and inexperienced olives can ensure that accuracy of their dispatched merchandise. They do that with the assistance of colour sorters.

This apparatus makes use of high-tech optical sensors that may acknowledge even the slightest chromatic distinction within the pieces passing in the course of the chute. It’s extremely used by meals companies that procedure rice, grains, herbs, and sugar.

Conclusion

Taking further steps to ensure the protection and pride of your shoppers will probably be an important funding that can aid you reap rewards and build up your final analysis ultimately. Keep in mind that you don’t acquire client believe in a single day. You’ll must paintings exhausting for it, and it is going to display within the consistency and high quality of the goods you place available on the market.