Provide-chain resilience has develop into a sizzling matter in lots of meals production boardrooms in recent times because of a number of elements.

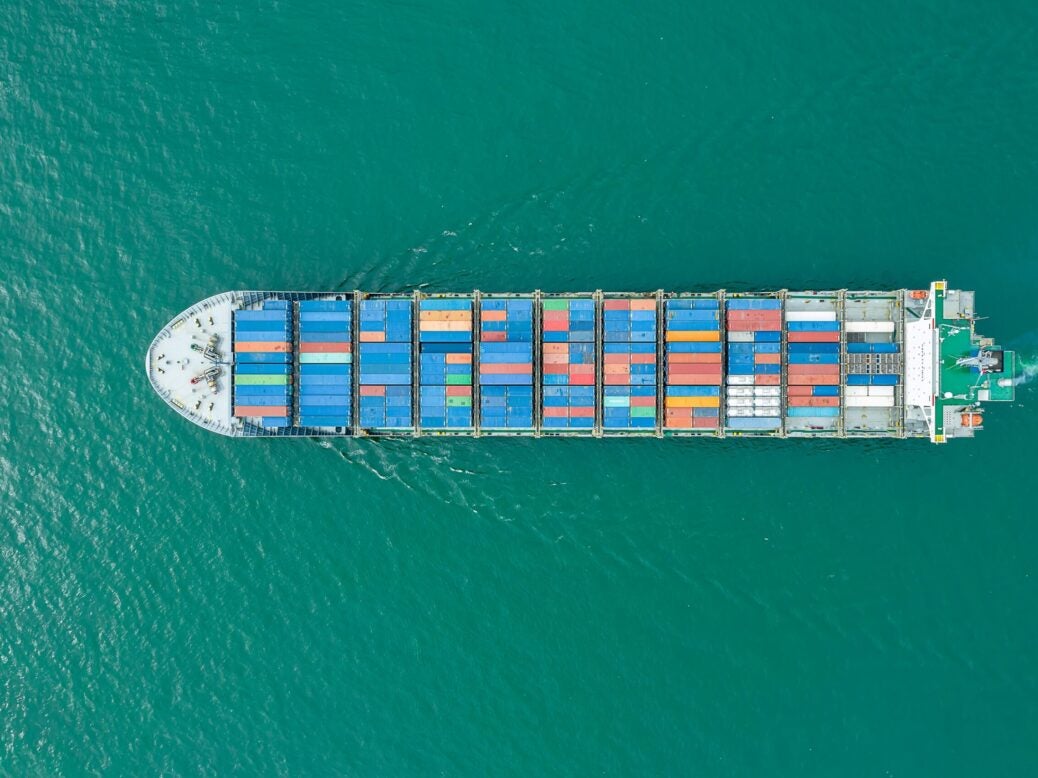

For plenty of meals producers running in Europe, and in particular the ones uploading or exporting items out and in of the United Kingdom, at the beginning, there used to be the problem of Brexit to deal with. Then there have been more than a few geopolitical problems rising in numerous international hotspots, adopted through freak incidents just like the Ever Given container send getting caught within the Suez Canal and blockading all transport site visitors, which had a devastating affect on delivery chains and companies during the arena. On best of all of that, the Covid-19 pandemic wreaked havoc globally, with many firms necessarily compelled to close down operations for sustained sessions.

Previous to this maelstrom of problems, many meals producers have been already browsing at how you can make their delivery chains extra powerful in order that they may face up to shocks. They have got additionally been putting in delivery chain methods to verify they may begin to meet ESG commitments, together with emission relief objectives which can be slowly however indisputably being imposed on them through outlets.

Ultimate 12 months, Andy Searle, a managing director and spouse at control experts AlixPartners, used to be satisfied that offer chain resilience could be a significant center of attention for lots of meals teams in 2022. On the other hand, now he’s no longer so positive, thank you largely to the continued disruption led to through problems such because the pandemic and hovering power costs, because of this many meals teams are purely taken with maintaining their trade ticking over.

“In relation to a few of these larger strategic questions [around supply chain resilience], I believe other people don’t essentially have the bandwidth to do it these days and they’re additionally ready to peer how issues calm down,” says Searle. “Obviously, Covid has highlighted one of the most dangers of a world, just-in-time, delivery chain with safety of delivery and threat and disruption all over. We’ve now were given to a spot the place it’s no longer simply transportation prices which can be going up – it’s all enter prices. Labour prices, power prices, and so on. So, in the case of what the trade case could be [for putting in place supply chain resilience measures], it’s nonetheless in flux as a result of there are many transferring portions and it’s unclear as to when or how it’ll all calm down.”

Hamish Renton, managing director at UK-based world food and drinks consultancy HRA World, has the same opinion the present tricky buying and selling stipulations have projects on delivery chain resilience positioned at the again burner. “I believe other people were skirting around the resilience of delivery chain from a number of other angles, in particular in a reactive approach, however they’ve no longer actually sat down and idea how, in an excellent global, would I construction it to present most resilience to what I’ve already were given? So, it’s been checked out, however it’s been checked out tactically, and no longer strategically through companies.”

Cyrille Filott, international strategist for person meals, packaging and logistics at Rabobank, believes conversations about delivery chain resilience have taken position at a boardroom degree, however thus far there was little process.

“The considering has began, however the implementation of that considering – those strategic processes – take a very long time,” he says. “So, it would take a couple of years sooner than you actually see this going down. However will it occur? Maximum no doubt, on account of long-term drivers corresponding to call for for native [products] through shoppers, the structural inflationary pressures after which ESG and particularly emissions.”

Courses from start-ups

One house the place professionals consider vital funding is wanted is upstream to verify delivery chains can face up to any ongoing disruption from such things as a plague, and in addition to mitigate waste.

“Meals teams will want to make investments as linear price chains need to be changed through round operations, with cut back, reuse and recycle as the brand new norm,” says Mirko Warschun, spouse and managing director within the lead person industries and retail follow Europe at AT Kearney. “Lately, we recycle about 10% of our fabrics. To hit science-based objectives, we want to building up this to no less than 40%. Reaching this goal would require vital adjustments in the best way CPG producers perform. The normal meals trade is being disrupted through agile start-ups. Via leveraging agile running fashions and a consumer-centric manner, start-up manufacturers are rising faster than the normal avid gamers.”

Steve Basili, international person merchandise running fashion transformation resolution chief at EY, additionally thinks some international meals producers may just be told from start-up disruptors about how you can configure – or reconfigure – their delivery chains.

“One of the crucial new meals/meat selection startups which can be rising aren’t within the trade of producing – they’ve created a community of native contract producers in addition to partnerships with main, established distribution avid gamers, which allows them to go into a marketplace at scale temporarily, with in the community related choices,” says Basili. “Their price is within the innovation and IP of the goods, and they are able to flex the manufacturing as wanted founded upon shifts available in the market. As a result of they’ve organised themselves to perform with their ecosystem companions on this method, they’re well-positioned to evolve to various kinds of disruptions, in addition to frequently search for avenues to cut back waste.”

After all, most of the international meals behemoths don’t seem to be so fleet of foot and will’t essentially simply pivot to this sort of versatile fashion. So, what may we think to peer those teams doing to shore up their delivery chains once they’re no longer distracted through all the different elements impacting their trade these days?

Searle says a just right start line is for corporations to actually perceive their delivery chains and take a look at attainable pinch issues. “Whilst you take into accounts resilience are you too depending on a unmarried node – a unmarried manufacturing unit, unmarried provider, and so on? And if they’re close down or blocked and you’ll be able to’t delivery in or out what does that then imply in the case of selection answers?” he says.

“So, perhaps you need to have selection nodes that you’ll be able to paintings via, be {that a} other nation, other provider, and so on. Should you’ve were given two other providers then obviously you de-risk there, but when they’re in the similar town, the similar nation, the similar house, then what I believe Covid has taught us is you most likely want to unfold your eggs throughout extra baskets.”

Searle provides agility could also be a key attention for companies “as a result of you want the power to switch between them [different suppliers] and so then you want the capability to allow that and you want to have the bandwidth for your organisation to facilitate that considering as properly”. He provides: “We’ve were given used to a gentle global the place we will do marginal enhancements in productiveness, and so on, however do now we have organisations that experience sufficient agility, resilience and bandwidth in themselves to regulate and take into accounts all of the disruption on the earth.”

Is nearshoring an answer?

One possibility professionals consider some meals producers may imagine to mitigate contemporary disruption is nearshoring – each in the case of providers of fabrics and the manufacturing of products – as a result of many were stung over the previous couple of years getting necessary provides out of positive international locations, or through the fast upward thrust in the price of transport bins from puts like China.

Filott thinks that as a large number of processing already occurs just about the markets meals teams are serving it’s not likely many will glance to shift manufacturing amenities, however there might be adjustments to the best way fabrics are sourced.

“As an example, the place do you supply your plastics from – is it from anyone close by?” he says. “And it’s the similar for agricultural commodities? Will have to I supply them from afar with all of the dangers that involves or must I am getting them from shut through? Nearshoring is much more likely to happen on the providers to meals producers – so the plastic firms, the paper firms and even perhaps step one processing of goods from the farm.”

On the other hand, Hani Alexander, US delivery chain and technique and transactions spouse at EY, explains the nearshoring manner isn’t essentially going to paintings for all companies. “Just about all firms are re-looking on the strategic architectures in their delivery chains,” says Alexander. “It’s been cited through shoppers as the number 1 precedence to restoration and past – forward of transparency and resiliency, and sustainability – and may just result in 8-15% price and money financial savings from community footprint optimisation and a 15-25% relief in lead instances. Discovering the correct delivery chain technique for the provision chain archetypes in operation doesn’t essentially imply a turn to close shore, however extra of a regarded as technique: the place to stick lengthy, lean, a ways shore, as opposed to the place to be close to shore, responsive and agile.”

One house that it’s extremely most likely all meals teams will imagine exploring when browsing on the strategic structure in their delivery chains and how you can lead them to extra resilient, is the higher use of era.

Rory Gopsill, affiliate analyst at GlobalData, feels the 2 issues that experience the best attainable to strengthen delivery chain resilience are AI and the Web of Issues (IoT). “IoT collects information from manufacturing websites, which an AI then analyses. This research provides higher visibility into the operations of a manufacturing web page, which is able to then be changed accordingly to make the whole delivery chain extra environment friendly, resilient, and so on,” he says.

Gopsill additionally thinks robotics may just play an important position – in particular throughout the context of the continued Covid-19 pandemic. “Robots can prohibit the difficulties led to through social distancing measures in manufacturing amenities through a) doing jobs corresponding to sanitation that can not be finished through an worker operating from house and b) changing human workers at the manufacturing unit flooring to make efficient social distancing a extra life like risk.”

No matter measures meals producers in the end make a decision to put into effect, what’s transparent is, for all of the speak about delivery chain resilience over the previous couple of years, thus far there was little or no motion. That would alternate over the following few years however Searle concedes that it’s too tricky to learn the runes because of all of the disruption happening on the earth these days.

“Whilst you checked out it closing 12 months, it is advisable to more or less get a way that transferring against being resilient used to be going to be a key factor going ahead, however it hasn’t actually took place. It hasn’t actually took place, I believe, as a result of other people were actually busy and looking forward to stuff to calm down,” says Searle. “Roll ahead 3 to 5 years, can we nonetheless be in a length of disruption the place issues nonetheless haven’t settled down, will now we have settled again to the established order, or can we be in a brand new scenario the place other people have checked out this and develop into extra resilient?

“It’s relatively tricky to determine which state of affairs we will be able to be in, however I believe the a success firms could have almost certainly idea via what’s the problem in each and every state of affairs and the way do you get some optionality or make alternatives that paintings in both case to make their delivery chains extra resilient.”